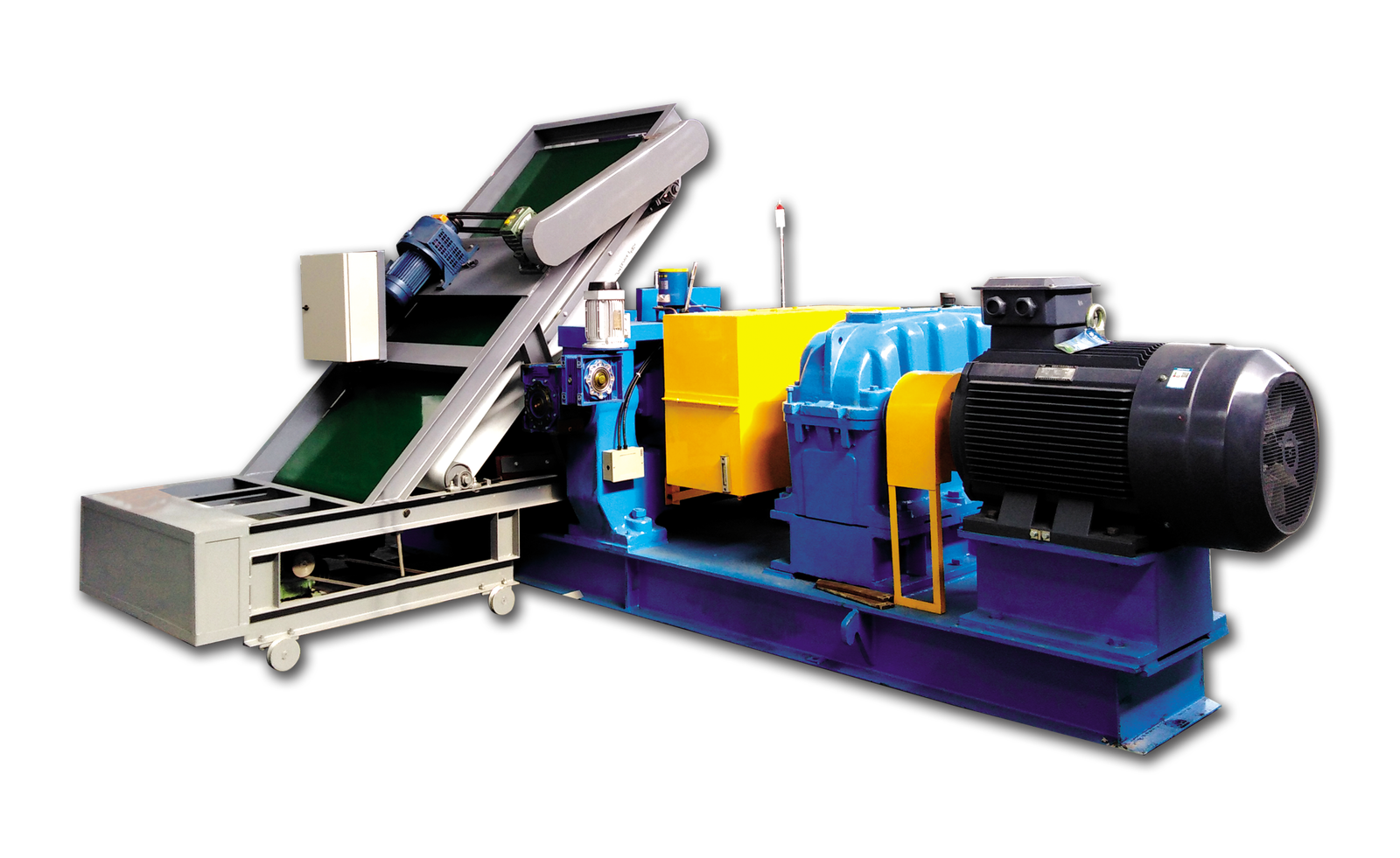

Yoga Mat Scraps Recycling Process

Foamed rubber including NBR,NR…Which is applicated in some insulation materials,sound insulation materials,yoga mat… the leftovers or scorched rubber compounds… all can be recycled and reuse as new rubber compounds…

Principle of rubber recycling process is rebuild the rubber bounds.

Additional information

| Applications | Foamed Rubber |

|---|---|

| Capacity | 30-110KG/h |

| Finished Products | Green Reclaimed Rubber |

| Power | 75KW |

| Rubber Waste | Foamed Rubber Scraps and Scorched Rubber |

Recycling Process

It can recycle the foamed rubber under normal temperature and pressure in short time. Principle of rubber recycling process is rebuild the rubber bounds.

Product Details

Product description:

Appearance: white powder

| Properties | Standard | Test result |

| Non-sticky temperature,℃ | ≤55℃ | 50℃ |

| Heat Loss,% | ≤1.3% | 1.1% |

|

Ash,% |

≤28% | 25.2% |

Solubility: Soluble in acetone, benzene, carbon tetrachloride and naphtha with medium solubility

Mode of action:

First,adjust the roll pitch of the mills to the minimum(zero pitch), put 100 parts (by weight) foamed rubber scraps or leftovers and 2-3 parts by weight of RV-RE rubber recycling chemical to the mills, and mill for 10 min so that they can be evenly blended; then adjust the roll pitch to 0.5 mm, compound rubber for 5 min mixing before sheeting. The roll temperature of the mill should be below 70℃.

It is recommended to use the refining mill, which has good effect and high efficiency; the whole process can be finished only in 10 min.

Properties:

RV rubber reviving technique is one way of rubber recycling by cutting S-S bond without influencing S-C bond and C-C bond.

The recycled materials can be used as raw rubber compounds to replace some parts of the new rubber compounds, which will not influence properties of the final products.

RV rubber recycling chemical is safe, color stay, non-pollution, non-blooming

The process is completely without any air pollution and water pollution, and is in accordance with environmental protection requirement.

The RV revived rubber products made by the RV rubber reviving technique are completely odorless, tasteless and are widely used with high value.

Dosage:

2-3PHR

Packaging:

Packaged in woven bag lined with polyethylene film, net weight 25kg/bag

Storage stability:

Two years keep in dry places without direct sunlight.