Silicone Rubber Board Recycling Process

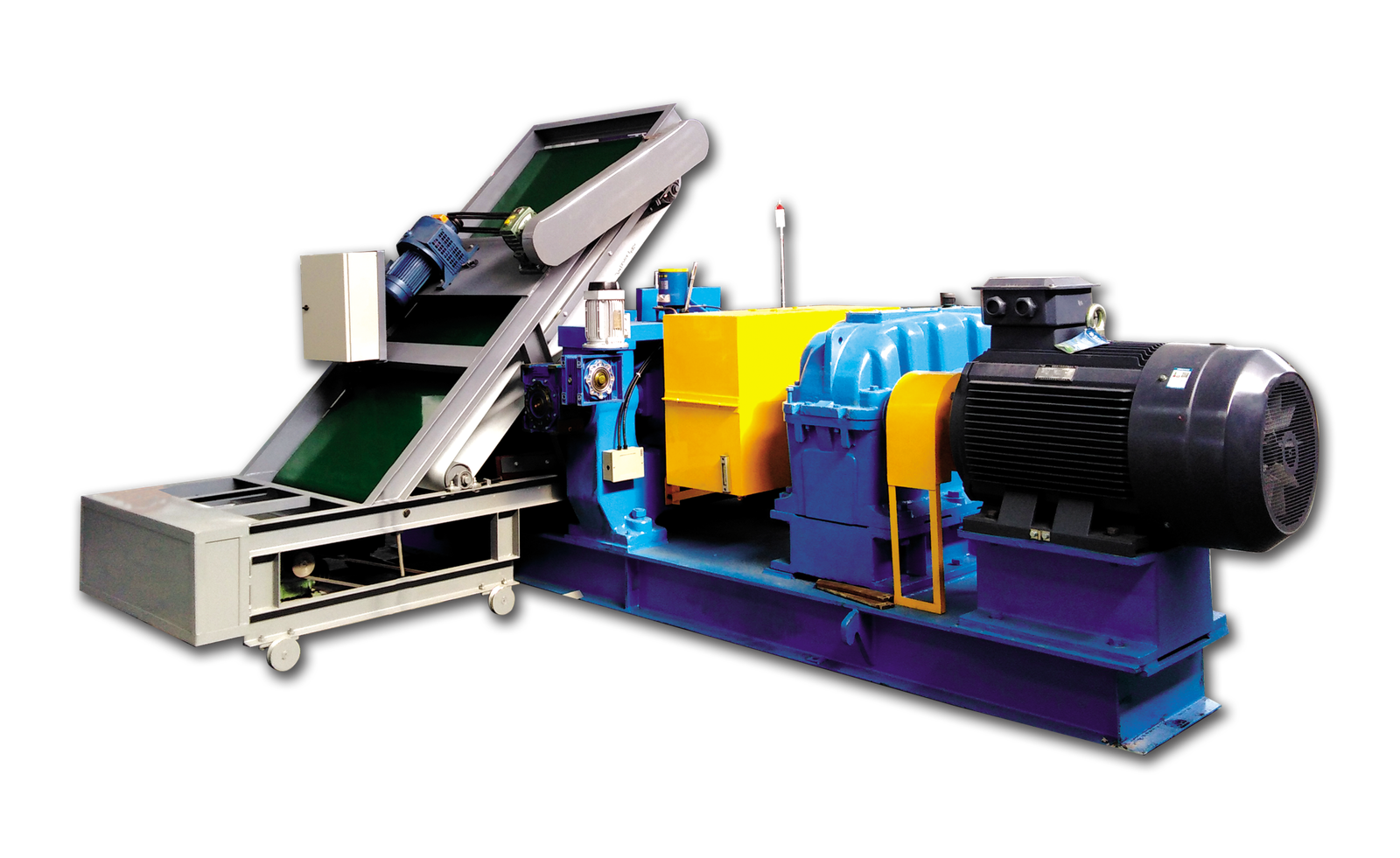

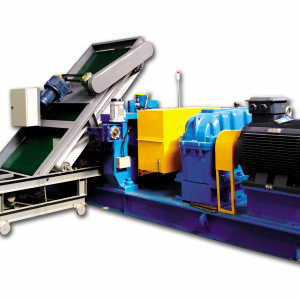

Technique Process:

Firstly, turn the roll pitch of the open mill to the minimum (zero pitch, add the rubber (10-40 meshes) or 100 parts by weight of the waste rubber leftovers and 2 parts by weight of the rubber reclaiming agent RV Rubber Recycling Chemical to the open mill, mill for 12 min and mix evenly; then sheet out.

The roll temperature should be below 70℃.

Using the refining mill has a good effect and high efficiency, and the whole process can be finished in 8 min.

Additional information

| Applications | Rubber Scraps,Rubber Powder,Rubber waste leftovers |

|---|---|

| Capacity | 30-110KG/h |

| Finished Products | Recycled Rubber Compounds,Reclaimed Rubber |

| Power | 75KW |

Recycling Process

Devulcanization is the process by which, by breaking the crosslinks between chains (sulfur or peroxide),

vulcanized rubber is re-transformed into a new plastomeric material, thus making it re-processable and recyclable.

Product Details

Silicone Rubber Scraps Recycling Technique

- First cut the silicone rubber products into small pieces (we have special crusher )

- Then the small pieces of vulcanized silicone rubber leftovers are crushed on a special designed two-roll mill.

- After crushing, add silicone rubber recycling additives, if necessary, add softeners to press into rubber sheet

- Add vulcanizing agent (we add DCP) to mixing into sheet

- Vulcanized into new silicone rubber products