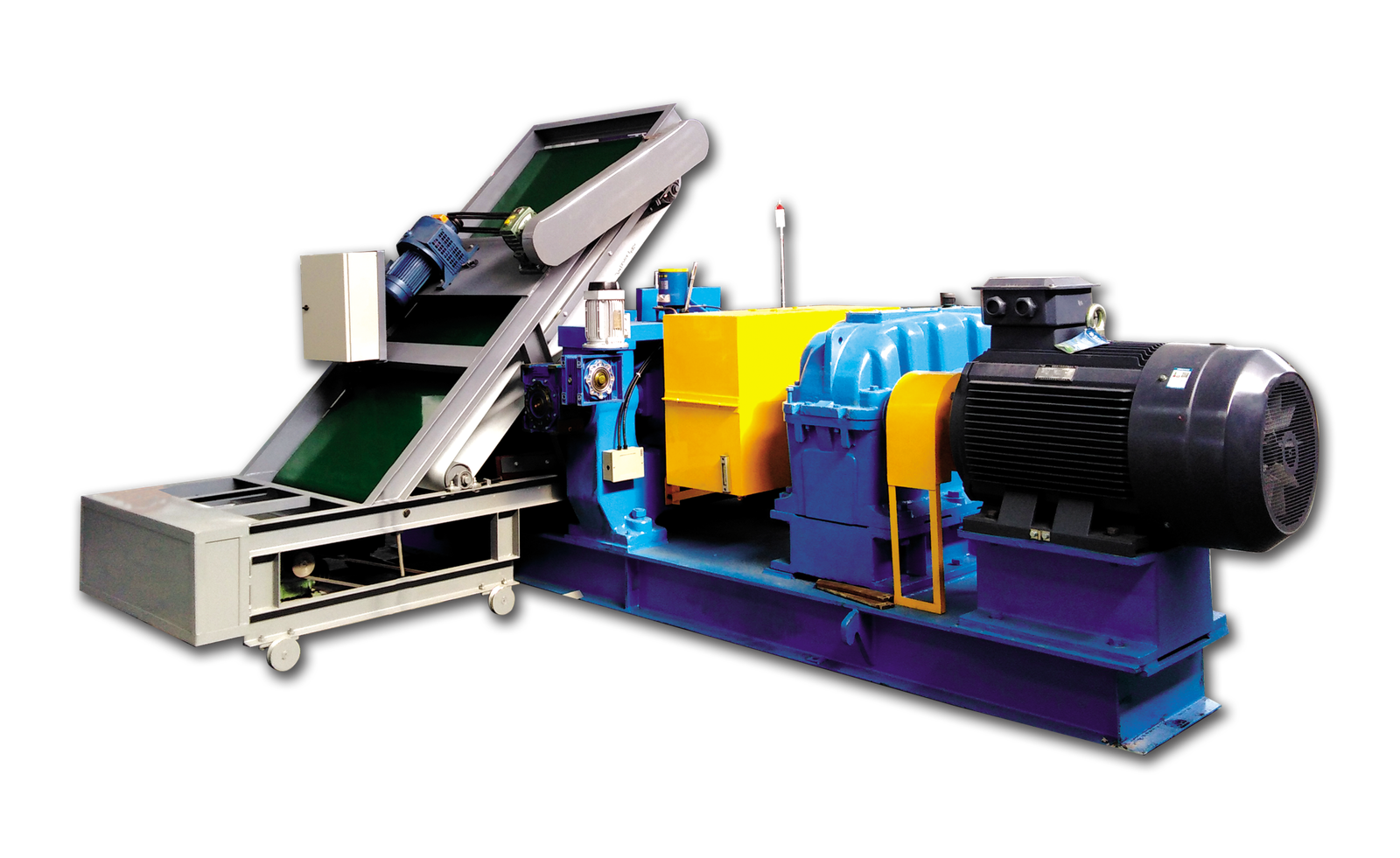

Fluororubber Gaskets Recycling Process

Fluorine rubber has good heat resistance, weather resistance, ozone resistance and excellent chemical stability and is one kind of self-extinguishing rubber. It is widely used in the aviation, aerospace, guided missile, rockets and many other high-tech areas, so as in petroleum, chemical industry, machinery and instrument; as the speed of the automobiles is increasing, the use of fluorine rubber in automobile industry is wider and wider, and the consumption of the fluorine rubber is greater and greater. As the price of the fluorine rubber is expensive, so is that of the fluorine rubber products, the recycle of the waste fluorine rubber is a good way to reduce the cost of the fluorine rubber products. The RDFPM (II) fluorine rubber reclaiming agent technique is simple and has obtained good effect. Our company can provide the application company with technical guidance and training.

Additional information

| Applications | Fluororubber Recycling |

|---|---|

| Capacity | 30-110KG/h |

| Finished Products | Green Reclaimed Rubber |

| Power | 75KW |

| Rubber Waste | Fluororubber,FKM |

Recycling Process

Brief Introduction of Fluorine Rubber Recycling Technique:

The refining mill→ put in waste fluorine rubber→ put in RDFPM(II) fluorine rubber reclaiming agent→ the process will be finished after sheeting.

Product Details

Application Recipe Property of the Reclaimed Fluorine Rubber:

|

Raw Material |

Recipe No. | ||

| 1# | 2# | 3# | |

| FE2604 | 100.00 | 100.00 | 100.00 |

| Carnauba wax | 1.00 | 1.00 | 1.00 |

| Ca(OH)_2 | 6.00 | 6.00 | 6.00 |

| MgO150# | 3.00 | 3.00 | 3.00 |

| AF–50 | 3.00 | 3.00 | 3.00 |

| FB–52 | 1.30 | 1.30 | 1.30 |

| Reclaimed Fluorine Rubber | 0 | 20.00 | 30.00 |

| Total | 114.3 | 134.30 | 144.3 |

| Vulcameter180℃ | |||

| ML | 1.12 | 1.28 | 1.41 |

| MH | 7.80 | 6.84 | 6.82 |

| T10 | 74 | 80 | 83 |

| T50 | 101 | 116 | 121 |

| T90 | 178 | 208 | 212 |

| Vulcanization Condition | |||

| First curing 180℃×6 min | |||

| Post curing 230℃×24h | |||

| Hardness | 52.6 | 55.3 | 56.3 |

| Strength | 8.15 | 11.02 | 10.26 |

| Elongation | 436.33 | 361.06 | 375.28 |

| M100 Set stretching stress | 1.37 | 1.52 | 1.64 |

| Tearing strength | 8.55/16.46/16.2 | 8.11/19.18/17.63 | 20.80/21.30/19.78 |

| Density | 1.8631 | 1.8648 | 1.8629 |

| Hot air aging 230℃×70h | |||

| HS | 58 +6.4 | 58 +2.7 | 60.5+4.2 |

| TB | 8.24 -0.91 | 10.94-0.8 | 12.22+1.96 |

| EB | 337.13 -22.7 | 363.5+2.42 | 391.9+16.62 |

| M100 | 1.26 | 1.46 | 1.60 |

Data Analysis and Conclusion:

Seeing from the above test data, the vulcanization speed of the compound rubber added with 20 or 30 parts by weight of reclaimed fluorine rubber is lower than that of the compound rubber without adding any reclaimed fluorine rubber, but it is not obvious, just adjusting the vulcanizing system a little is fine. The physical property and the hot air aging property are very close to each other.