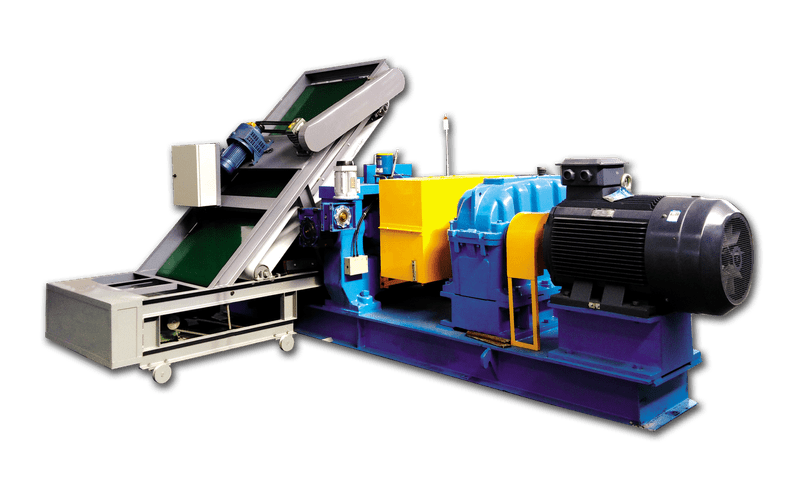

Rubber Leftovers Recycling Machine

Technique Process:

Firstly, turn the roll pitch of the open mill to the minimum (zero pitch, add the rubber (10-40 meshes) or 100 parts by weight of the waste rubber leftovers and 2 parts by weight of the rubber reclaiming agent RV Rubber Recycling Chemical to the open mill, mill for 12 min and mix evenly; then sheet out.

The roll temperature should be below 70℃.

Using the refining mill has a good effect and high efficiency, and the whole process can be finished in 8 min.

Additional information

| Applications | Rubber Scraps,Rubber Powder,Rubber waste leftovers |

|---|---|

| Capacity | 30-110KG/h |

| Finished Products | Recycled Rubber Compounds,Reclaimed Rubber |

| Power | 75KW |

Recycling Process

Devulcanization is the process by which, by breaking the crosslinks between chains (sulfur or peroxide),

vulcanized rubber is re-transformed into a new plastomeric material, thus making it re-processable and recyclable.

Product Details

Technique Process:

Technique Advantages:

The revived rubber can vulcanize without adding any vulcanizing agent and accelerator, which can save the processing aid valued 500 yuan, (GB/T13460-2008 the standard recipe of the reclaimed rubber is: reclaimed rubber 300g,accelerator NS 2.4g,zinc oxide 7.5g, sulfur 3.5g, stearic acid 1.0g; of which one ton of the reclaimed rubber need to consume the processing aid valued 500 yuan to vulcanize production),so one ton of the waste rubber only needs the reclaiming agent valued 200 yuan to revive to the rubber product.

If 20% of the revived rubber is used to substitute the raw compound rubber, the dosage of the accelerator in the raw compound rubber can be reduced about 20%, which can further save the costs about 100 yuan. At present, RMCD rubber mechanochemical chain scission depolymerizing agent (hereinafter referred to as RV rubber recycling chemical) is suitable for the application of deep products.